Captive Molder Beefs Up Auxiliaries to Boost Quality, Consistency

SeeScan adds conveying, drying, feeding and chilling technologies to improve quality — and enhance employee safety — in production of its underground/underwater inspection systems.

A captive molder recently made sweeping changes to its fleet of auxiliary equipment and as a resulted achieved a completely integrated system that improved the quality and consistency of its molded parts while significantly enhancing operator safety.

Based in San Diego, SeeScan Inc. makes a wide range of vision systems and instruments that help locate utilities and inspect pipes in what the company describes as a mission “to make the underground visible.” At a 120,000-ft2 facility, SeeScan molds its own parts on eight injection presses of 20 to 330 tons. It runs a gamut of engineering thermoplastics, including ABS, PC, nylon and PEI, either neat or glass-filled in a range of colors.

L-r: Martyn Bramhall of Bramac Machinery; Mike Mueller, Moretto regional sales manager; Kirk Joy, SeeScan director of tooling. (Photos: Moretto)

Last year the company initiated a project aimed at upgrading the auxiliary equipment in its plant, with the objective to address some inefficiencies with its previous machines and add more automation to the process, relying less on operators to move materials around. It decided on Moretto, adding eight new dryers and conveying systems, three loss-in-weight gravimetric feeders and a new temperature-control system.

Solving a Resin Moisture Problem

On the drying side, SeeScan was using a rack-mounted central system that was especially problematic on overnight runs. Explains SeeScan’s Director of Tooling Kirk Joy, “Before the night shift, we would transport enough material to the presses to satisfy an overnight run. But we noticed as time progressed that we would be picking up moisture in the process. The parts we made at the beginning of the evening were not the same as those throughout the evening and into the morning.”

SeeScan uses Moretto feedthroat-mounted compressed-air mini dryers for applications requiring 12 lb/hr or less.

After consulting with Moretto’s West Coast sales representative, Martyn Bramhall of Bramac Machinery, SeeScan bought three different styles of Moretto dryers. These included the feedthroat XD Mini Series compressed-air dryer, which SeeScan deployed on smaller presses for micromolding jobs; XComb wheel dryers; and XD cabinet dryers. All Moretto dryers come with anti-stress (over-drying protection) as standard, notes Mike Mueller, Moretto regional sales manager.

“We do everything from micromolding to running parts requiring a 330-ton press,” Joy explains. “The fact that Moretto has a variety of drying technologies to address our needs and to help us improve consistency has been advantageous. And providing us the ability to drying without having to worry about overstressing our materials during long production runs was one of the key technologies that stood out to us. That feature has also allowed us to save lot on energy,” he adds, which nowadays is critical virtually everywhere but particularly in high-cost states like California.

Cart-mounted cabinet dryers are for applications requiring 20 lb/hr, or higher if furnished with a VFD turbo compressor.

Controlling Color Consistency

Along with drying challenges, SeeScan was looking to upgrade from a labor-intensive color-feeding process. Says Joy, “We had previously been mixing color concentrate with virgin resin manually. An operator would fill the material into bucket, add the color concentrate at the desired letdown ratio, then we’d mix it and put in into the cold hopper. This process was creating a number of issues. At the top of the list was employee health and safety; our operators were regularly handling and picking up barrels of material.” SeeScan went with a trio of Moretto’s DPK gravimetric loss-in-weight color feeders.

“The color feeder has enabled us to maintain consistency through a very accurate dosage of color concentrate with virgin materials and it does so automatically, so there is no manual handling of materials,” says Joy. The units also self-tune to account for bulk-density variations in the material, adds Mueller.

DPK loss-in-weight color feeders helped SeeScan automate what had been a highly labor-intensive process.

In addition to the three feeders, SeeScan bought additional hoppers that it keeps filled with color on the shelf. “This allows us to store our color concentrate without worrying about any debris infiltration and allows for ultra-fast color changes. All we need to do is purge, switch the hoppers, and we’re ready to go,” says Joy.

“We are able to decrease scrap significantly because of the accuracy and consistency provided by the feeder,” he adds. “The machine-mounted color feeder also integrates well with our process. It doesn’t take up any floor space and doesn’t get in our way when we want to hang tooling.”

Meantime, SeeScan added Moretto’s TWP12S High Temp water-temperature control unit, which Joy says is ideal for this plant because it runs so many high-temperature materials: “With high-temperature materials, a lot of times the water temperature will run up to 320° F. That will ruin conventional pump seals. This TCU has a magnetically coupled pump, so there is no pump seal. It also has all-solid-state controls, which is helpful.”

“The fact that Moretto has a variety of drying technologies to address our needs and to help us improve consistency has been advantageous.”

States Joy, “With Moretto, what we ended up with was a completely integrated solution — from conveying material to blending, drying and more— that has improved our consistency and reliability and significantly enhances operator safety.”

Related Content

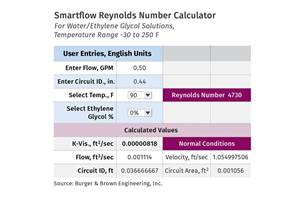

Cooling Geometry and the Reynolds Calculation

The original Turbulent Flow Rate Calculator worked well with a round circuit diameter, such as a drilled passage, but not as well using hydraulic diameters. Here’s how the problem was fixed.

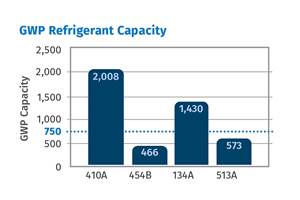

Read MoreTemperature Control: What You Need to Know to Comply With New Cooling-Fluid Regs

Beginning the first of this year, 12 states are following EPA bans on potentially damaging cooling fluids. Chiller suppliers have adjusted equipment designs to accommodate the new regulations. Here’s what all this means to processors.

Read MoreHow to Reduce Sinks in Injection Molding

Modifications to the common core pin can be a simple solution, but don’t expect all resins to behave the same. Gas assist is also worth a try.

Read MoreImprove The Cooling Performance Of Your Molds

Need to figure out your mold-cooling energy requirements for the various polymers you run? What about sizing cooling circuits so they provide adequate cooling capacity? Learn the tricks of the trade here.

Read MoreRead Next

People 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreFor PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read More (2).jpg;maxWidth=970;quality=90)

(2).jpg;maxWidth=300;quality=90)

(1).jpg;maxWidth=970;quality=90)