With proper care and maintenance, aluminum tooling can reach the million shot mark and beyond, as found by Honda’s multiyear study and by others. There is not one set of guidelines to follow for aluminum tooling maintenance, but rather each aluminum tool needs a maintenance plan that is customized for that specific tool.

There are several factors in determining a maintenance plan for aluminum tooling. Type of resin to be molded, any mechanical actions in the tool, gate type, and whether a coating has been added are just some of the factors to consider when determining a maintenance schedule.

Design In Potential Part Changes

Whenever possible, during the design phase of a mold, it is beneficial to know of any potential part revision areas that might occur down the road. If any such areas are known upfront, the mold can be designed with an insert in the area that could potentially change. Doing this upfront may slightly increase the original tooling price but will be more cost-effective when a revision is needed later on. This is not to say that inserting cannot happen later, because it can and does happen quite often. However, there are occasions where after-the-fact inserting would sacrifice the integrity of the tool and therefore would require a complete rebuild.

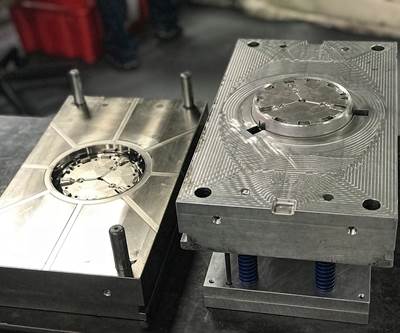

This aluminum mold has produced close to 200,000 shots of ABS in four cavities, with a logo removal and hard-coat stripping and reapplication midstream.

Inserting an aluminum mold is the preferred option vs. welding, because the latter can leave a pitting effect, and the weld will be softer than the rest of the mold. For best results in welding aluminum, the welding rod must be equivalent to the aluminum of the tool. Proper prepping is also required to avoid welding issues. Inserting high-wear areas, such as slide-by shutoffs with minimal draft or the gate area when using highly abrasive resins, is also a good practice to consider with aluminum tooling.

Resin’s Impact on Tool Life Expectancy

Several material-related precautions need to be addressed to extend the life expectancy of an aluminum injection mold. Filled resins will tend to wear out the shutoffs and the gate area, but one of the precautions that can forestall that wear is a Nibore coating. Adding a Nibore surface coating of about 0.0002-0.0003 in. to an aluminum tool raises the surface hardness up to 50-56 HRC. This process can usually be done in about three days and can always be stripped and recoated if the coating starts to show wear. The coating is also good at reducing the amount of oxidation that occurs in an aluminum mold, and it acts as a release agent when ejecting the part off the tool.

Thanks to its thermal advantages, an aluminum mold’s process window is typically larger than steel’s, but processors should beware of excessive temperatures and pressures.

If a coated aluminum tool needs another coating or a part revision is required, the coating can be removed, machined or welded. In the image above, you will see the customer requested a logo removal. The tool was machined to remove the hard coating, then welded and polished. The next step involves stripping and adding another hard-coat application if it would be required for cosmetic reasons. In this case, the parts were acceptable without re-coating. To date, this mold has produced close to 200,000 shots in four cavities using ABS resin.

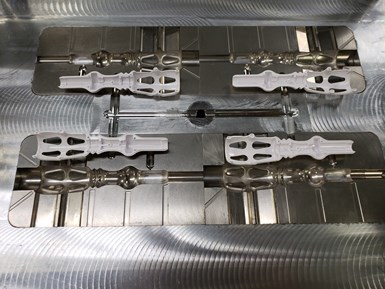

If possible, mechanical actions are preferred over a manual operation for a few reasons. Cycle times will be faster and more consistent, which results in a shorter residence time in the barrel. Often, a manual action will also require a pull-fixture to properly remove the hand load from the molded part to prevent part distortion. Any time a hand load is used, the chance of an operator placing it carefully back in the tool the exact way every shot is highly unlikely. Not to mention the fact that there is the possibility of the hand-load getting damaged when handled outside of the mold, as workers rush to keep the cycle time as low as possible. In addition, for maintenance reasons, mechanical actions are better options than hand loads since they usually require less preventive maintenance and repair, because the hand loads can potentially be mishandled during the cycle.

With experience and strong procedures in place, an aluminum mold can produce 1 million shots-plus on many occasions and with multiple resins.

Process Parameters Affect Aluminum Tool Maintenance

What happens while an aluminum mold is in the press can in some ways be just as important as what happens when the tool is on the bench for routine maintenance. Molding practices are different when comparing an aluminum mold to a steel mold and should be implemented as such. Excessive temperatures and injection pressures can damage a tool rather quickly and eliminate any possibility of a long life expectancy. Whether it is detail shifting under high injection pressures, or galling from extreme temperatures, the integrity of the tool can be reduced rapidly. Normally the process window for aluminum is greater versus a steel mold due to its improved thermal advantages.

A Routine Maintenance Routine

Aluminum molds should be taken apart and cleaned thoroughly after every run of parts. The frequency that this should happen is largely dependent on the resin that was used to mold the product and whether there are actions in the tool. Often, an aluminum injection mold can run five to seven days before needing to be cleaned, but other cases may require a cleaning after two to three days, for various reasons. Regardless of how short the run is, aluminum molds should be cleaned once they’re removed from the press and prior to storage ahead of the next order of parts. Checking for wear and/or galling should also be part of the routine maintenance that is done every time a mold is removed from the press.

Whether your molds are built from steel or aluminum, all preventive-maintenance practices are vital. With experience and strong procedures in place, an aluminum mold can produce 1 million shots-plus on many occasions and with multiple resins. It is important to note that routine maintenance also promotes optimal performance and high-quality parts. Considering that, and aluminum’s thermal advantages, the material is a strong choice for many molds produced today.

ABOUT THE AUTHOR: Scott Lammon is v.p of tooling at Phoenix Proto Technologies, Centreville, Mich. He has been with the company and in the moldmaking and plastics industry for more than 25 years and was a designer/programmer prior to assuming his current position. Contact: 269-467-8300; scott.lammon@phoenixproto.com; phoenixproto.com.

Just like their steel counterparts, aluminum tools should be taken apart and cleaned thoroughly after a part run and prior to storage.

Related Content

Impacts of Auto’s Switch to Sustainability

Of all the trends you can see at NPE2024, this one is BIG. Not only is the auto industry transitioning to electrification but there are concerted efforts to modify the materials used, especially polymers, for interior applications.

Read MorePEEK for Monolayer E-Motor Magnet Wire Insulation

Solvay’s KetaSpire KT-857 PEEK extrusion compound eliminates adhesion and sustainability constraints of conventional PEEK or enamel insulation processes.

Read MorePlastic Compounding Market to Outpace Metal & Alloy Market Growth

Study shows the plastic compounding process is being used to boost electrical properties and UV resistance while custom compounding is increasingly being used to achieve high-performance in plastic-based goods.

Read MoreCelanese to ‘Shine’ at CES 2023 with Expanded Portfolio of Materials

With it acquisition of DuPont’s engineering resins, Celanese’s resin solutions for automotive electrification, e-mobility and consumer electronics are plentiful.

Read MoreRead Next

Aluminum Tooling Answers Hard Questions

Check your preconceptions about aluminum production tooling at Phoenix Proto’s door.

Read MoreAluminum Tooling Proves Its Mettle

Can aluminum tooling enter the race for high-volume automotive injection molding?

Read More

(2).jpg;maxWidth=300;quality=90)