By now, everyone has heard of lean manufacturing and may even apply lean principles in some form or fashion to their process. The lean concept is credited for anything done better today than yesterday by means of some type of formal or informal improvement process.

Practicing lean manufacturing principles helps alleviate wasted motion in the process. For example, better labeling certainly helps reduce scrap and increase uptime in profile extrusion, but lean manufacturing itself does not go far enough to solve the labor shortage issues many processors confront today. The majority of plastic processors live in the world of short runs that dictate multiple changeovers each day on each extrusion line. Operators are trained over and over, and processors are attempting to find the top talent and turn each operator into the top tier of their operator classification pool. These efforts don’t always achieve the desired results.

With finding labor being an ongoing problem, many manufacturers have turned to automation as a solution. But automation is not always practical; or in some cases the return on investment is too small to justify the outlay. When automation does not make sense, processors must think about lean manufacturing by focusing on ways to reduce operator interaction with the Process (ROIP).

Practicing lean manufacturing principles helps alleviate wasted motion in the process.

How specifically can ROIP be applied in profile extrusion? Here are a few examples:

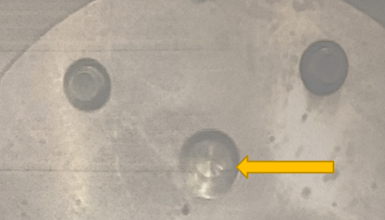

• Tooling Adaptors: In a typical custom extrusion shop, multiple adaptors are used for the different sizes of profiles, or various material needs drive requirements for a different tooling adaptor. With lean manufacturing techniques, manufacturers are getting better at stamping a code into the various adaptors to ensure adaptor Part A goes with adaptor Part B. Documentation has increased to ensure the correct tooling goes together and the operators are trained to follow the documentation. Using ROIP in this same scenario ensures the tooling is built and configured so that Part A cannot physically bolt onto Part B (see Fig. 1). Thus, the documentation and training are no longer a major focus, or in many cases, even required.

FIG 1 Shown here is a Part A female side of an adaptor. Part B will have a stud. (Images: T. Groth)

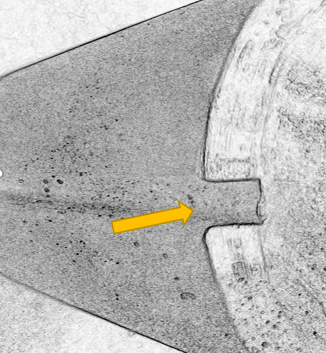

• Cutting Bushings: Nearly every extruder has some sort of cutting device at the end of the line. The blade-cut type of devices have a matched set of bushings. The operator is given directions, via setup documents, on which bushings to use. However, the alignment of the bushings for the profile to go through without hitting on the exit bushing is left up to the operator physically looking through the bushings.

This is often extremely difficult to do in a machine where space constraints—not to mention safety constraints—put the operator in an uncomfortable ergonomic position. When applying the ROIP method in this situation, have your toolroom cut a keyway in the bushings when they are being made so that it matches the keyway system in the cutter for a one-time installation (see Fig. 2).

FIG 2 This shows the Part A female end of a keyway in a matched set of bushings. The cutting device is fitted with the Part B male keyway (arrow).

Following the ROIP methods, the exit bushing should be cut 0.002-in. larger than the entrance bushings. The exit bushing should also be cut up to 0.020-in. larger on any non-critical cutting edge. Any position on the bushing not receiving cutting interaction at the supporting base of the bushing where the plastic is met, requires the larger clearance.

• Die-Circumference Variation: Extrusion shops tend to have different circumferences on their tooling. Circumferences have either changed by design or, in some cases, were made necessary by phased-in process improvements. Having differently sized tooling, in turn, means you need to have differently sized heater bands. (See March 2022 article on the five heater-band principles.)

Processors need to adopt ROIP thinking throughout the process to get ahead of the labor constraints in the current market.

With various sizes of tooling, the processor is left with supply rooms full of small to large heater bands, requiring the operator to choose the correct band. When applying the ROIP method in this scenario, a simple aluminum ring can be made for each tool to make the circumference the same. An added benefit of the ring is that the operator does not have to make decisions on wattages and autotune controllers. Figure 3 is an example of a ring used to increase the circumference on a smaller tool.

Processors need to adopt ROIP thinking throughout the process to get ahead of the labor constraints in the current market. Processors must stop thinking in terms of training in tribal knowledge and increasing documentation and instead think in terms of engineering out the operator’s interaction with the process.

FIG 3 Aluminum ring shown here is used to increase the circumference on a smaller tool.

There will always be a need to train operators on understanding the science behind the extrusion process, but practice ROIP principles where possible as well.

ABOUT THE AUTHOR: Tim Groth has more than 37 years of hands-on extrusion experience, specializing in design for extrudability, tooling design, troubleshooting, material selection, plant setup, training of engineers and setup technicians, and practicing Lean Manufacturing principles. He is currently dir. of engineering for consulting company Extrusion Solutions North LLC, Hastings, Minn. Contact: 651-357-0814; timtgroth@gmail.com.

Related Content

Cooling the Feed Throat and Screw: How Much Water Do You Need?

It’s one of the biggest quandaries in extrusion, as there is little or nothing published to give operators some guidance. So let’s try to shed some light on this trial-and-error process.

Read MoreFully Automated Extrusion Process Enables Use of Composites for Manufacturing Pressure Tanks

Amtrol was looking for a more cost-effective means to produce thin-wall liners for a new line of pressure tanks. With the help of a team of suppliers, they built one of the world’s most sophisticated extrusion lines.

Read MoreHow to Effectively Reduce Costs with Smart Auxiliaries Technology

As drying, blending and conveying technologies grow more sophisticated, they offer processors great opportunities to reduce cost through better energy efficiency, smaller equipment footprints, reduced scrap and quicker changeovers. Increased throughput and better utilization of primary processing equipment and manpower are the results.

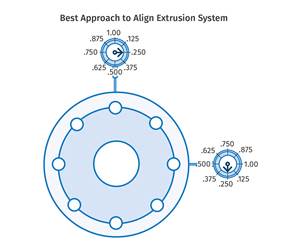

Read MoreExtruder Alignment: Important, but Only Half the Equation

The other half? Aligning and supporting downstream equipment. Here are best practices.

Read MoreRead Next

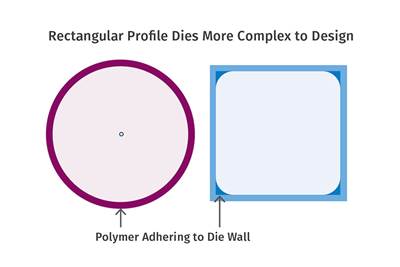

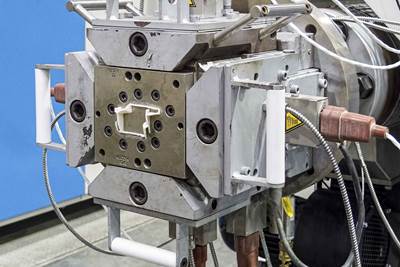

Extrusion: Follow These Tips to Get Profile Die Design Just Right

Calculating polymer flow is fairly straightforward when designing a die for a simple round profile, but as the shapes get more complicated these calculations can get extremely challenging. Here’s what you need to consider.

Read MoreIs Your Profile Die the Problem? Or Is It the Heaters?

When a profile is not being extruded to the tolerances of previous runs, the die is often suspect—but the real problem may be the heaters. Learn the five heater-band principles before you do any profile die work.

Read More

(2).jpg;maxWidth=300;quality=90)