Compounding & Mixing at NPE 2003

Torque levels and output capacities of corotating twin-screw compounders coming to NPE are higher than ever.

Torque levels and output capacities of corotating twin-screw compounders coming to NPE are higher than ever. The most recent news comes from Japan Steel Works (JSW), which is increasing its U.S. market presence with the establishment of a sales and technical center in the Midwest. JSW will show a new “ultra-high-torque” line of i-Tex corotating twin-screw compounders with 20% higher torque than the previous D-Tex models that were built here under license by Davis-Standard until three years ago.

There are also some unusually flexible corotating twin-screw lab lines on display. German Technology Imports’ new GIGA-34 lab model has 80 hp and can function like two different machines. At under 800 rpm, it’s a lab line. At 1800 rpm, it’s a pilot plant capable of compounding up to 800 lb/hr.

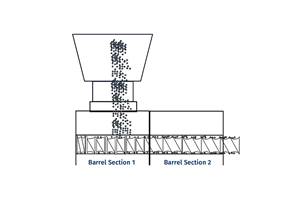

Labtech Engineering Co. in Thailand is bringing a new 26-mm corotating twin-screw extruder that’s four machines in one. It has interchangeable barrels for single- or twin-screw operation, both in 32:1 and 40:1 L/D.

Though not brand-new, one of the most unusual mixing devices at NPE is the 12-screw Ring Extruder from 3+ in Germany. At the show, its U.S. representative, Century Extruders, is raffling a chance to use the machine for trials in your own facility later this year.

Pelletizers advance

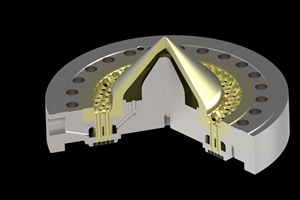

As filler levels and abrasiveness increase, compounders are chewing through pelletizer knives and dies at an ever-growing clip. Several show exhibitors are offering knife-sharpening and hardening services. But one of the more novel developments in the battle against abrasion is a patented ceramic pelletizer die and die plate from Econ GmbH in Austria. Believed to be the world’s first, it will run recycled PE at Starlinger’s booth.

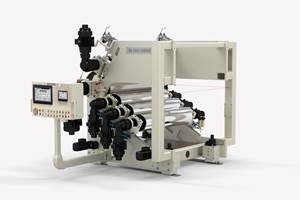

In other pelletizer developments, Scheer Bay Co., a U.S. partner of C.F. Scheer in Germany, will show a new 15-strand lab pelletizer with a high-speed option that lets it cut up to 300 ft/min or 1300 lb/hr. Meanwhile, Conair’s new Model 216 increases output 30% by adding 30% more strands.

Abrasive materials and higher throughput are also noisy, so pelletizers are getting added sound deadening. Cumberland’s Super Quietizer strand pelletizer muffles the infeed and encloses the pelletizer with acoustic foam. The same features are available on a comparable new AEC model. Dynisco’s redesigned WRP 12i water ring pelletizer also boasts lower sound levels, higher throughput, and more uniform pellet size.

Static mixers haven’t changed much in recent years, but there is a new supplier at NPE that has licensed new manufacturing technology from Bayer in Germany that reportedly makes the mixers very much stronger and more resistant to crushing on cold start-up. Stamixco LLC says the Bayer process also allows the mixers to be made and sold at lower cost.

Higher mixing intensity

If it’s speed you’re after, Draiswerke is introducing a Gelimat thermokinetic batch mixer that delivers batches of compound in just 5 to 20 sec, thus providing an extremely short heat history. An electronic temperature sensor tells when compounding is complete and ejects the batch through a discharge door into a melt pump, short extruder, or calender. Draiswerke says the Gelimat is well suited to mixing recycled plastic with wood flour or other organic or inorganic fibers.

Related Content

How to Configure Your Twin-Screw Extruder for Mixing: Part 5

Understand the differences between distributive and dispersive mixing, and how you can promote one or the other in your screw design.

Read MoreGreen’s the Theme in Extrusion/Compounding

The drive toward circular economy is requiring processors to make more use of PCR. Machine builders at K—across all extrusion processes—will be highlighting innovations to help them do just that.

Read MoreHow to Configure Your Twin-Screw Extruder -- Part 2

Follow these tips to configure your twin-screw elements to promote feeding and solids conveying.

Read MoreHow to Maintain Pelletizing Quality When Acid Attacks

Developments in the chemistry of polymers and additives have made corrosion a real problem in pelletizers. Here’s how to ward it off.

Read MoreRead Next

Lead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read MoreMaking the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read More