New Way to Characterize Moldability Of Resins & Part/Tool Designs

Experienced injection molders have long known that a resin’s melt flow index (MFI), measured under very low-shear conditions, provides very little information about how it will process under many orders of magnitude higher shear in an actual mold.

Experienced injection molders have long known that a resin’s melt flow index (MFI), measured under very low-shear conditions, provides very little information about how it will process under many orders of magnitude higher shear in an actual mold. They know, for example, that two materials of the same MFI can process quite differently, and a material of a lower MFI can sometimes process much easier than one with a higher MFI.

A better alternative is to use a capillary rheometer to produce curves of viscosity vs. shear rate, which clearly show changing viscosity caused by shear thinning. However, such curves provide mainly relative moldability comparisons; the units of measurement (Pascal-seconds for viscosity and reciprocal seconds for shear rate) are of no practical value in judging a resin’s process window.

A novel solution to this problem was presented at NPE2012 in Orlando, Fla., last month by Beaumont Technologies Inc., Erie, Pa. As explained by CEO Dr. John Beaumont, his new Therma-Flo “moldometer” not only characterizes the injection moldability of polymer melts in a practically useful form, but it goes beyond all existing rheometers by measuring flow under the thermal conditions the melt “sees” when flowing through a cooled mold. Beaumont’s moldometer uses an actual injection molding machine, which fills a “mold-like apparatus” that contains 15 different geometries—some that resemble a modified trapezoidal runner, ranging in diameter from 0.040 to 0.180 in.; and some that resemble a cavity geometry from 0.020 to 0.120 in. thick. The system is designed to index automatically through the various geometries, filling one at a time, and molding parts in each geometry over a range of 10 injection speeds. With five repetitions for each speed, that amounts to 750 molding trials for each material. The flow channels have direct melt sensors to measure pressure and velocity with a high-speed data-collection system.

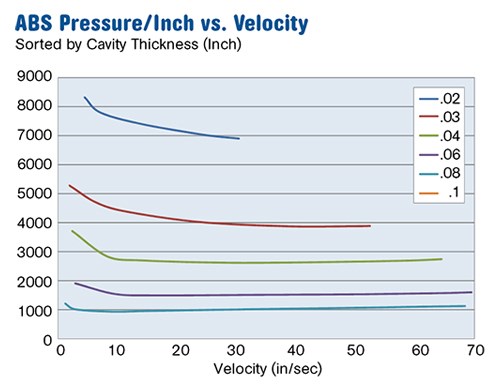

The accompanying graph shows a characteristic “moldometer flow sheet,” which is unlike anything produced by a typical rheometer. It shows the melt pressure in psi/in. required to flow a material through cavities of different thickness. The curves shown here for ABS display a typical drop in pressure required to go from very low speed to higher speed, as a result of shear thinning. More surprising is the fact that,

after the initial drop, the curves tend to level off, requiring little or no increase or decrease in pressure per inch of flow at higher and higher speeds. This would not be predicted from capillary rheometer curves, which show steadily declining viscosity at higher shear rates (related to flow speed). Beaumont believes that further research will establish a material’s “critical velocity” at which the moldometer’s psi/in. data can

be extrapolated to predict filling pressures in molds of any size. The “critical velocity” is the condition where the melt will not freeze off during filling because heat loss to the mold is exactly balanced by shear heating.

Beaumont sees many applications for his new material characterization method: comparing flowability of different materials or formulations; predicting ability to fill a mold within the pressure limitations of a given injection machine; and verifying the predictions of computer mold simulations.

Related Content

50 Years of Headlines … Almost

I was lucky to get an early look at many of the past half-century’s exciting developments in plastics. Here’s a selection.

Read MoreInjection Molding Simulation Meets the Real World

Direct data interface between molding simulation and the injection machine links the computer model to the real-world process. This can improve results from product and mold design through ongoing production. A case study demonstrates these benefits for automotive components in a family mold.

Read MoreTake Time to Save Time: Five Steps in Mold Design to Reduce Back-End Troubleshooting

Westminster Tool shares how the one week it typically takes to perform these five steps in the design phase can save three weeks or more in an overall tool build.

Read MoreHow to Achieve Simulation Success, Part 2: Material Characterization

Depending on whether or not your chosen material is in the simulation database — and sometimes even if it is — analysts will have some important choices to make and factors to be aware of. Learn them here.

Read MoreRead Next

Recycling Partners Collaborate to Eliminate Production Scrap Waste at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair will seek to recover and recycle 100% of the parts produced at the show.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read More

(2).jpg;maxWidth=300;quality=90)