NPE2018 New Technology Focus: Compounding

Check out what’s new in compounding at this year’s big plastics industry trade show.

Leistritz Extrusion (W5545) is displaying a ZSE 18 system consisting of loss-in-weight feeders, a co-rotating twin-screw extruder, gear pump, and die to produce 1- to 5-mm 3D-printing filaments. Downstream, the line is equipped with a custom air rack for air-quench cooling and sizing of the filament, plus a belt puller, laser gauge and winder. The control system will integrate closed-loop pressure control to ensure a tight-tolerance product.

Leistritz is also showing a ZSE 50 MAXX twin that includes modular barrels and screws and an insulated barrel cover. The ZSE 50 MAXX can be equipped with a 600-hp AC motor to produce more than 2200 lb/hr at 1200 rpm.

The LSB XX series side stuffer is supplied with a high OD/ID ratio of the screws (2.0:1) and can also convey materials with very low bulk densities. The screws can be segmented so they can be configured for a particular material.

Leistritz is displaying various control architectures, including Allen-Bradley and Siemens PLCs and operator interfaces. The company will also debut its Elongational Rheometer. This device mates to an extruder; a small amount of the melt flow is diverted, measured and returned to the extruder to facilitate on-line analysis and adjustment of shear and elongational viscosities.

Entek Extruders (W5189) is showing two machines in its booth: a new QC3 33-mm twin-screw extruder, introduced in 2017 and being shown publicly for the first time; and a high-output 73-mm twin-screw.

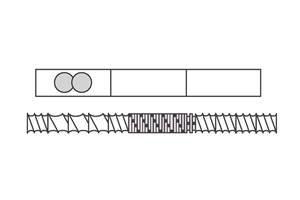

The Entek QC3 33-mm co-rotating twin-screw is a new size. It’s designed for compounding small lots and includes all of the company’s latest QC3 (Quick-Change, Quick-Clean and Quality Control) features. The 33-mm unit joins Entek’s other QC3 models, which include 27-mm, 43-mm, and 53-mm co-rotating twins. New mechanical design features in the 33-mm model include self-aligning screw-gearbox couplings to facilitate fast and foolproof installation of screws; lock-and-key feature on splined shafts to prevent screw timing errors; conveniently located gauges for quick monitoring of lube and cooling-system conditions; quick-change strand die; and enhanced controls.

Entek is also featuring a 73-mm twin geared for high-output custom compounding. It’s available with a 600-hp motor and screw speeds up to 900 rpm. Entek will have two interactive work stations at its booth where visitors will be encouraged to see how easy it is to quickly design screw and barrel layouts for their specific applications.

With color masterbatch in mind, Coperion Corp. (W729) has equipped its STS Mc11 twin-screw with features that significantly improve the system’s handling and ease of cleaning. A new base-frame design allows for integration of the water manifold and wiring connections for better cleanability without sacrificing accessibility.

Operations around the machine are reportedly simpler since Coperion reengineered the extruder covers to enable easy access to the process section and at the same time reduce dust contamination. The unit also includes a smoother surface for easier cleaning. The barrel heater shells are equipped with insulation plates to minimize the temperature on the surface of the process section. The barrel feed opening is fitted with a removable sleeve, which facilitates simple cleaning and therefore quicker color changes. A tray has been added to the vent port to collect drippings or vent flow. And the die head has been redesigned so it can now be quickly opened by simply loosening swing bolts for faster color changes.

The STS 35 Mc11 exhibited at NPE2018 is equipped with a Coperion K-Tron K2-MV-T35 volumetric twin-screw feeder—billed as an economical and reliable solution for metering color premix batches. The T35 feeder handles free-flowing to very poorly flowing powders (e.g., lumpy, moist or bridging materials) as well as fibers, flakes and other bulk materials.

Related Content

Twin-Screw Showcased in Circular Economy Demo

NPE2024: A KraussMaffei twin will upcycle pelletized blood vials, which will then be overmolded on another press to produce bottle openers.

Read More10 Ways to Improve Twin-Screw Compounding Performance

There are many techniques known to operators and plant engineers for increasing the performance of a twin-screw compounding extruder.

Read MoreProgram Helps Compounders Configure Screw, Barrel Layout

New software from ENTEK is said to make it easier for compounders to design their own screw and barrel configurations.

Read MoreConfiguring the Twin Screw Extruder: Part 4

For many compounding operations, material is fed to the extruder at the feed throat. This is the case when feeding a single polymer or a blend of polymers mixed with solid additives. Some ingredients, however, present a challenge in feeding. Here’s how to solve to them.

Read MoreRead Next

Making the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read More