Extrusion: The Importance of Zone 1 Barrel Temperature

Tweaking the temperature settings of the first barrel zones may not yield the desired result. In fact, they may yield the opposite. Here’s why.

Perhaps the most misunderstood part of the extrusion process is the effectiveness of the barrel temperature in Zone 1. In the feed section of the extruder, the solids are always well below the melt temperature (unless melt fed) and the screw conveys them forward in auger-like fashion. They become compacted from the drag and frictional forces acting upon the particles. During compression, some pressure develops in the solid polymer as it is forced into intimate contact with the barrel wall.

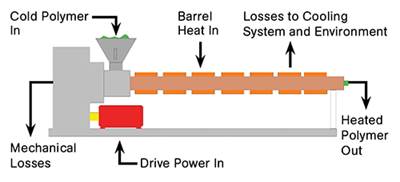

The sooner you can start melting, the more efficient the whole process, as it essentially lengthens the effective screw length. (Photo: Davis-Standard)

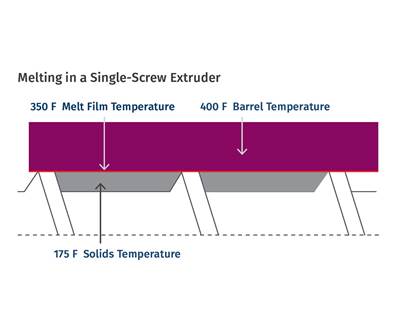

With the screw rotation and resulting sliding/shearing of the compacted mass against the barrel wall, as well as some conducted heat from the barrel, the solids adjacent to the barrel wall accumulate enough energy to form a thin layer of melted polymer on that surface. This usually occurs from one to three diameters after the cooled feedthroat and is often referred to as the “delay in melting.” From that point the forwarding force or output depends on that thin film dragging the solids underneath.

Although the conducted heat from the barrel contributes to the initial formation of melt layer or film, the majority of the energy to initiate melting comes from the frictional drag of the polymer against the barrel wall. That’s because polymers are very poor conductors of heat, evidenced by the fact that it often takes several hours to melt the polymer in a cold extruder before it can even be started up.

The majority of the energy to initiate melting comes from the frictional drag of the polymer against the barrel wall.

Once initiated, the melt film becomes an intermediate layer between the barrel and the underlying solids. That layer absorbs most of the energy from the drive. Eventually a melt pool is formed on the pushing side of the flight and melting progresses. As a result, the first barrel zone does not always react as you might expect. Cooling Zone 1 below the melting point of the particular polymer delays melt formation and thereby effectively shortens the melting length of the extruder—and likely the output. Since the barrel is highly thermally conductive compared to the polymer, it pulls heat from the film if the temperature is set below the melting temperature.

Conversely, if the barrel is heated well above the melting point, it lowers the viscosity in the film, reducing its shear stress, resulting in a reduction in melting rate and output. Both reactions can be the opposite of the operator’s likely intentions and only serve to reduce the melting and potential output. If you look at the force balance in this system, the formation and viscosity of the initial melt at the barrel wall determine the output of the extruder. Obviously the rate it goes through Zone 1 determines the final rate of extrusion.

The power going into the polymer from the extruder drive is many times the total wattage of all the barrel heaters of most commercial-sized extruders, even under full heating power. So the barrel heaters are essentially for startup and some trimming of the barrel-temperature profile. That’s why I prefer the use of an “adiabatic” approach to barrel settings, with the exception of the first barrel zone, which can be instrumental in initializing the melt-film generation and output. The sooner you can start melting, the more efficient the whole process, as it essentially lengthens the effective screw length.

A good setting for Zone 1 is a temperature slightly above the melting point of the polymer.

Adiabatic approach refers to a barrel-temperature profile that does not add or remove much heat from the melt film once it’s formed. In other words, the temperature controls after Zone 1 are set so that they essentially do minimal heating or cooling after startup.

Zone 1 also has an additional effect on the feed rate by transferring heat to the feed throat. A warmer throat improves polymer-to-barrel friction, resulting in greater feed rates and better stability. A cold feed throat pulls heat from the beginning of Zone 1, reducing early polymer-to-barrel friction and early melting, which determines the output. A good setting for Zone 1 is a temperature slightly above the melting point of the polymer. That does two things: It eliminates removing heat at the initiation of melting; and it prevents greatly reducing the viscosity of the melt against the barrel.

ABOUT THE AUTHOR: Jim Frankland is a mechanical engineer who has been involved in all types of extrusion processing for more than 40 years. He is now president of Frankland Plastics Consulting, LLC. Contact jim.frankland@comcast.net or (724) 651-9196.

Related Content

A Simpler Way to Calculate Shot Size vs. Barrel Capacity

Let’s take another look at this seemingly dull but oh-so-crucial topic.

Read MoreDensity & Molecular Weight in Polyethylene

This so-called 'commodity' material is actually quite complex, making selecting the right type a challenge.

Read MoreHow to Select the Right Tool Steel for Mold Cavities

With cavity steel or alloy selection there are many variables that can dictate the best option.

Read MoreTunnel Gates for Mold Designers, Part 1

Of all the gate types, tunnel gates are the most misunderstood. Here’s what you need to know to choose the best design for your application.

Read MoreRead Next

Why Barrel Temperatures Have a Small Effect on Melt Temperature

Extruders are not like ovens. Tweaking barrel-temperature profiles will not influence melt temperature all that much. Here’s why.

Read MoreMission (Nearly) Impossible: Estimating Extrusion Melt Temperature

Extrusion processors often ask screw designers to estimate the output and melt temperature of a new design in the works. Projected output of a new screw can usually be estimated fairly accurately. Melt-temperature estimate, however, is another story

Read More

.jpg;width=70;height=70;mode=crop)