Uniloy Enhances Aftermarket Services, Renews Its Machinery Portfolio

NPE2024: At the show, Uniloy is highlighting its expanded service network and spare-parts capabilities, as well as a new tooling asset-management program and interactive electronic machine manual. Not on display are several new machinery developments across the company’s technology spectrum.

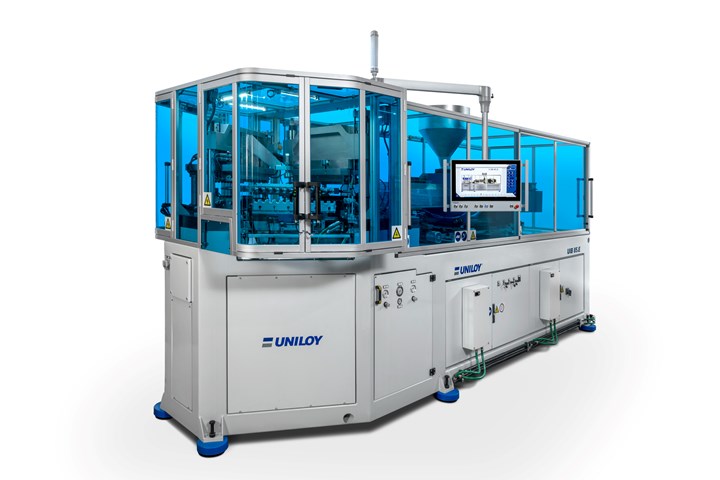

Uniloy’s first all-electric injection-blow machine, model UIB 85-E, is an 85-tonner aimed at medical and other “clean” applications. It’s the first of a new three-machine line. Source: Uniloy Inc.

Reflecting a business based largely on parts and service, Uniloy is highlighting several new programs in these areas at the show; but behind the scenes, it has begun launching the first fruits of a wide-scale machinery development program.

Among new aftermarket services, Uniloy is spotlighting its new asset-management program, called Mold Maintenance R&R (Repair and Refurbish). Started last year with selected customers, and now being rolled out to a larger audience, this program is aimed at customers have have tooling for several hundred cavities of the same bottle. It involves regular maintenance of tooling, some of which is stored at Uniloy for quick shipment to the customer when needed. “This way, customers can get refurbished tooling in 72 hr instead of the usual six to eight weeks,” says Uniloy CEO Gary W. Riley, Sr. “Also, there’s a set charge for the service, eliminating delays for quoting each job.”

In addition, Uniloy has increased its service staff almost tenfold over the last two years, through both new hires and certifying independent contractors after training at Uniloy University. The company also has invested millions of dollars in its Uniloy Genuine Parts business, increasing both quantities on hand and the range of part numbers by 30%. In the third quarter, the company will launch an online catalog and store, aimed initially at Uniloy’s reciprocating-screw machines, though it will be expanded later to injection-blow and shuttle extrusion lines.

Also new is an interactive electronic machine manual with schematics, bills of materials, safety videos, etc. It’s available first for Uniloy’s UR 100 reciprocating-screw machine.

Videos at the booth will also feature some of the wide range of machinery developments in the works at Uniloy – including its first all-electric injection-blow model (85 tons), the start of a new series; new servohydraulic reciprocating-screw models, starting with a UR 100 in a new 10-cavity version (up from eight cavities previously), which increases throughput 25-40% while using 20-35% less energy per bottle. And for shuttle machines, Uniloy has developed its own three-layer coextrusion head for encapsulating post-consumer reclaim.

Without revealing details, Riley hints that Uniloy plans to announce a moldmaking acquisition at the show. (At press time, it emerged that Uniloy purchased certain shuttle moldmaking and technical service assets and people from its longtime partner FGH Systems.)

Uniloy’s CEO, Gary W. Riley, Sr., says he learned from his family’s injection molding business that the way to help customers “become better and more profitable” is to help them improve “uptime, throughput and quality.” Source: Uniloy Inc.

Related Content

-

How Inline Vision Inspection Can Minimize Scrap in Molding

Once viewed by injection and blow molders as a necessary evil, machine vision technology today can continuously monitor and improve production while reducing costs.

-

How Was K 2022 for Blow Molding?

Over a dozen companies emphasized sustainability with use of foam and recycle, lightweighting and energy savings, along with new capabilities in controls, automation and quick changeovers.

-

Foam-Core Multilayer Blow Molding: How It’s Done

Learn here how to take advantage of new lightweighting and recycle utilization opportunities in consumer packaging, thanks to a collaboration of leaders in microcellular foaming and multilayer head design.