AI Software Extended to Multiple Fanuc Robots

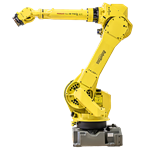

Micropsi Industries MIRAI software allows the Fanuc robots, including cobots, to be trained via hand guiding, and it lends “hand-eye” coordination for difficult-to-automate jobs.

Micropsi Industries’ AI-based MIRAI software MIRAI is now compatible with numerous robots produced by Fanuc, which joins Universal Robots in this compatibility. Micropsi says MIRAI will allow Fanuc customers to add hand-eye coordination to multiple Fanuc robots, including cobots, allowing them to take on difficult-to-automate functions such as cable plugging and assembly.

Using AI, the MIRAI controller generates robot movements directly and in real-time so that robot skills are trained, not programmed, through human demonstration. To train a robot, a human repeatedly demonstrates a task by manually guiding the robot by the robot’s wrist. The recorded movements are then transformed into a repeatable skill.

As an example of a difficult-to-automate task that the MIRAI technology makes feasible, Micropsi points to cable plugging applications such as flat ribbon cables for electronics or automotive connectors. These typically require a high degree of flexibility to accommodate shape instability, making it a difficult task for any robot. Micropsi Industries plans additional automation projects that will expand the range of applications for Fanuc’s industrial robots.

The MIRAI software lends Fanuc robots hand-eye coordination, making more complex automation tasks possible.

Photo Credit: Fanuc

Related Content

-

Automation in Thermoforming on the Rise

Equipment suppliers’ latest innovations exemplify this trend driven by factors such as labor shortages, higher-speed thermoformers and tighter quality control.

-

How Was K 2022 for Blow Molding?

Over a dozen companies emphasized sustainability with use of foam and recycle, lightweighting and energy savings, along with new capabilities in controls, automation and quick changeovers.

-

Drones and Injection Molding Ready for Takeoff

Drones and unmanned aerial vehicles (UAV) are approaching an inflection point where their production volumes — and functionality — will increasingly point to injection molding.