Application Records, Displays all Sustainability Relevant Process Data

KraussMaffei (KM) says new software provides in-depth process data by capturing up to 500 machine signals in real time for carbon footprint measurement.

Working together with auxiliary equipment supplier Motan, KraussMaffei says it has developed software to capture all sustainability related process data, helping processors account for the amount of carbon dioxide saved by recycling materials versus using virgin resin, among other capabilities.

Together with Motan, digital APC plus platform has been optimized to show the energy consumption of each process step, enabling processors to record and improve upon their energy consumption. Further, KM says APC plus has been adapted to the processing of reclaimed material and can help reduce production scrap by automatically adjusting to changing conditions during molding. During start-up as, KM say nominal process values are reached much faster, decreasing start-up scrap. KM says its dataXplorer captures up to 500 machine signals in real time for carbon footprint measurement, with any deviations from the pre-defined tolerance ranges detected instantly.

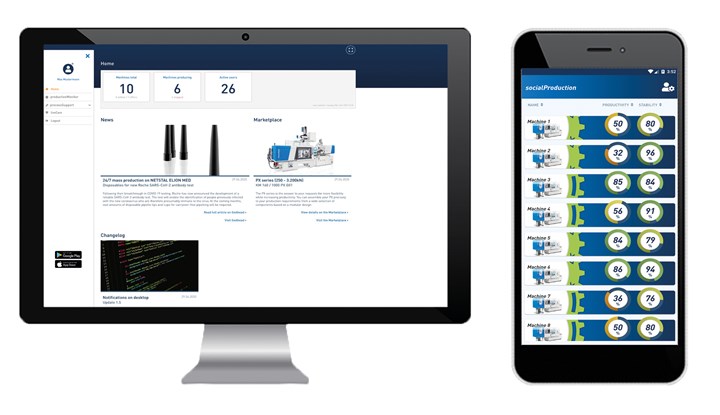

KraussMaffei’s digital assistant portfolio can help processors who want, or need, to be more cognizant of their environmental footprint, with offerings including liveCare, processSupport and productionMonitor, which are all part of its socialProduction suite of products. In addition, the company puts forward its e-commerce platform—pioneersClub.

KM notes that in the European Union plans are in place to introduce a digital product passport that would require manufacturers and OEMs to document, among other things, the materials used for each product and how they were processed. KM says the digital products it currently offers would enable processors to start moving in that direction.

A smartphone app and a web application for PC or tablet are available for KM’s socialProduction.

Photo Credit: KraussMaffei

Related Content

-

How Was K 2022 for Blow Molding?

Over a dozen companies emphasized sustainability with use of foam and recycle, lightweighting and energy savings, along with new capabilities in controls, automation and quick changeovers.

-

K 2022: ‘We’ve Been Waiting 40 Years!’

With sustainability top-of-mind in the plastics industry, this was a ground-breaking show for builders of recycling equipment. It also prompted new thinking in thinwall injection molding.

-

Green’s the Theme in Extrusion/Compounding

The drive toward circular economy is requiring processors to make more use of PCR. Machine builders at K—across all extrusion processes—will be highlighting innovations to help them do just that.