Smart Assistant Bridges Injection Molding Skills Gap

NPE2024: MAX the Process Advisor, as well as free presentations and training by RJG Inc.

RJG Inc. announces an innovative feature for its CoPilot process control system called molding automation xperience (MAX), the Process Advisor. MAX utilizes AI technology powered by Master Molder techniques to provide molders with real-time, expert guidance to optimize their injection molding processes. The technology will be available to demo at RJG’s booth.

Today, molders encounter an increasingly pressing and distinctive challenge: a shortage of skilled processors to troubleshoot their injection molding processes, resulting in excessive scrap, machine downtime and wasted engineering hours. RJG developed MAX to assist in bridging that skills gap and reducing waste during production.

This smart assistant monitors process parameters in real time and offers troubleshooting advice to help molders rapidly resolve issues and improve productivity. RJG’s MAX leverages AI to deliver high levels of control, efficiency and quality.

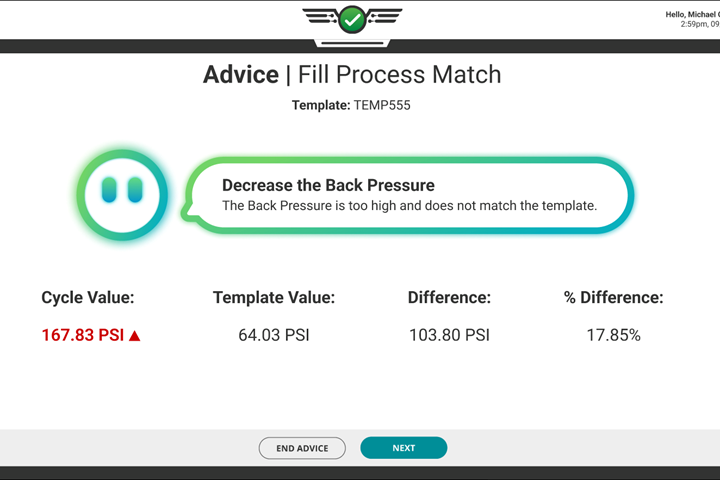

Featuring an intuitive and easy-to-use interface, MAX offers guidance to molders by delivering step-by-step instructions for restoring a process to optimal performance. This empowers personnel on the floor, regardless of their experience, to handle process issues effectively, enabling them to make an immediate impact.

Related Content

-

Improve The Cooling Performance Of Your Molds

Need to figure out your mold-cooling energy requirements for the various polymers you run? What about sizing cooling circuits so they provide adequate cooling capacity? Learn the tricks of the trade here.

-

How to Optimize Pack & Hold Times for Hot-Runner & Valve-Gated Molds

Applying a scientific method to what is typically a trial-and-error process. Part 2 of 2.

-

Are Your Sprue or Parts Sticking? Here Are Some Solutions

When a sprue or part sticks, the result of trying to unstick it is often more scratches or undercuts, making the problem worse and the fix more costly. Here’s how to set up a proper procedure for this sticky wicket.