scientific molding

'Engage, Innovate, Evolve': Future-Oriented Culture at Octex Group

Using science, technology, and talent to give high-tech customers unprecedented speed to market.

Read MoreDetermining Vent Depths in Injection Molding

Experiments reveal the relationship between vent depths and part thickness, allowing molders and moldmakers to more precisely determine vent dimensions.

Read MoreInjection Molding: Nozzle Heaters & Thermocouples: A Case of Wiring Done Wrong

Incorrect placement of wires for these components frustrates molders and costs them money to boot.

Read MoreInjection Molding: New Mold Trial—Will It Run 24/7?

Use this nine-step process to make sure you’ll be making good parts after a successful trial. But even then, be prepared for some hiccups.

Read MoreMaterials: Cycle Time—Science vs. Rules of Thumb, Part 6

This installment—on elastomers—completes a series, whose theme is to bring more science to the discipline of molding. The overall message: Ask a lot of questions whenever someone posits this or that ‘rule of thumb’ about processing.

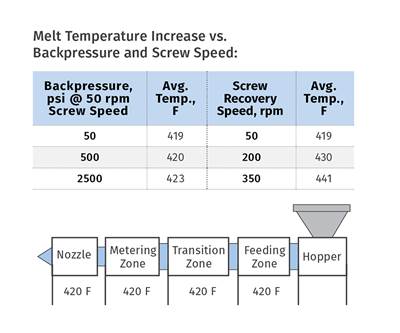

Read MoreInjection Molding: No, Backpressure Does NOT Raise Melt Temperature

It’s a classic confusion between cause and effect. Melt temperature rises when screw speed is increased. Check out this data.

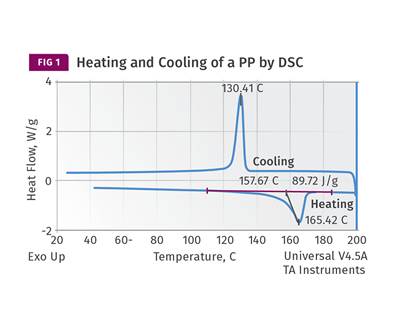

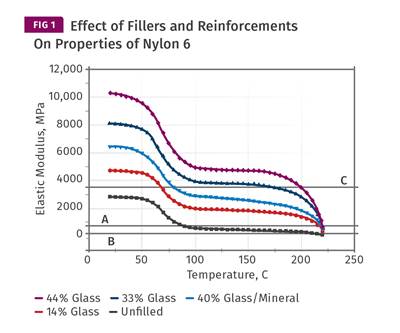

Read MoreMaterials: Cycle Time: Science vs. Rules of Thumb—Part 5

Let’s examine the behavior of semi-crystalline materials that never reach their glass-transition temperature as they cool.

Read MoreInjection Molding: DOEs Done Right

Doing DOEs for the sake of doing them wastes time and money. But they can provide vital information to determine which process variable is determining a critical part characteristic.

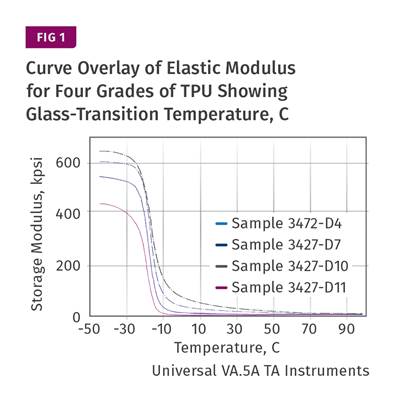

Read MoreCycle Time: Science vs. Rules of Thumb—Part 4

While laboratory tests are helpful in determining how polymers behave, you must remember the fundamental differences between laboratory measurements and the real world of plastic processing. Let’s examine semi-crystalline polymers here.

Read MoreInjection Molding: How Repeatable is Repeatability?

Process repeatability is not a constant, but varies over time in response to a number of variables. That variation is not captured by a snapshot in time—measuring a discrete sample of parts. And the only way to manage that variation is with process controls that adjust each and every cycle.

Read More

(2).jpg;maxWidth=300;quality=90)