Tooling Know-How

Part 1: The Basics of Tapered Interlocks

Various types of interlocks are available to molders. Here, we discuss the oldest and most common types of interlocks—those with a tapered or angular shutoff.

Read MoreWhat You Should Know About Injection Mold Safety Straps

Every mold should have one in order to be safe and OSHA compliant.

Read MorePART 2 OF 2: Tricks of the Trade on RTOs, RSOs

They have a lot more to offer molders than just shutting off a cavity. Let’s take a closer look.

Read MoreTricks of the Trade on RTOs and RSOs

The more you know about these runner diverters and shutoffs, the more you’ll use them. Here’s how to put them to work in your mold..

Read MoreTooling: Why Ejector Pins Break and How to Prevent It, Part 3

Here we focus on forces, friction, surface finish, and lubrication.

Read MoreTooling: Why Ejector Pins Break And How to Prevent It, Part 2

Here’s the when and how to reduce the unsupported length of pins.

Read MoreTooling: Why Ejector Pins Break...and How to Prevent It, Part 1

In part one of this four-part series, we focus on the molding machine and the ejection system as culprits.

Read MoreTooling: Clamp Pressure & Cavity Land Area, Part 2

What you need to know to prevent flashing and mold damage.

Read MoreTooling: Clamp Pressure and Cavity Land Area

What you need to know to prevent flashing and mold damage.

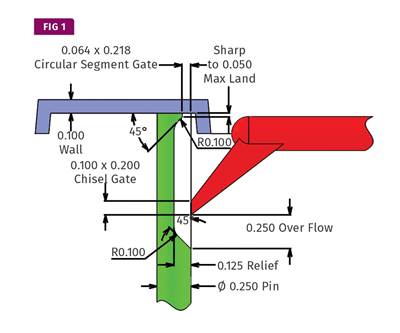

Read MoreTooling: What You Need to Know About Jump Gates

Many molders don’t care for jump gates because they have to process around them. But here are some tricks of the trade.

Read More

(2).jpg;maxWidth=300;quality=90)