best practices

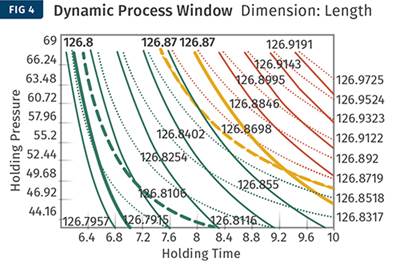

How to Optimize Pack & Hold Times for Hot-Runner & Valve-Gated Molds

Applying a scientific method to what is typically a trial-and-error process. Part 2 of 2.

Read MoreOptimizing Pack & Hold Times for Hot-Runner & Valve-Gated Molds

Using scientific procedures will help you put an end to all that time-consuming trial and error. Part 1 of 2.

Read MoreThe Importance of Melt & Mold Temperature

Molders should realize how significantly process conditions can influence the final properties of the part.

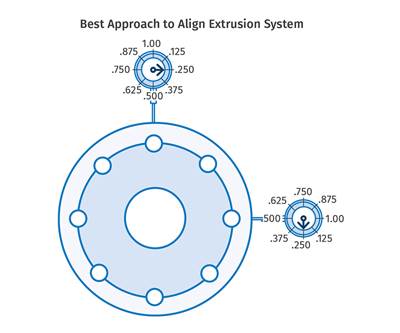

Read MoreExtruder Alignment: Important, but Only Half the Equation

The other half? Aligning and supporting downstream equipment. Here are best practices.

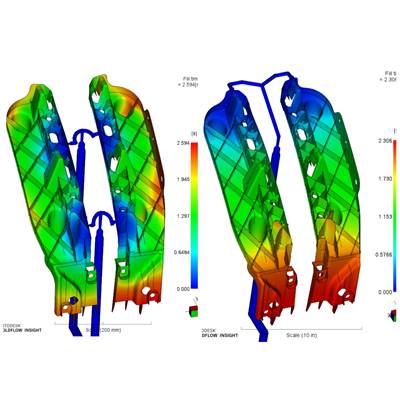

Read MoreWarpage Waylaid Via Simulation

Designed to form a component that would hold headlights in place, the mold was intended to produce a front-end automobile bracket. Instead of parts however, the tool’s real output was problems.

Read MoreUnderstanding Flow Fronts and Defects

Flow-front behavior and corrections are key to solving many common molding problems —what is your process’s flow trying to tell you about your part?

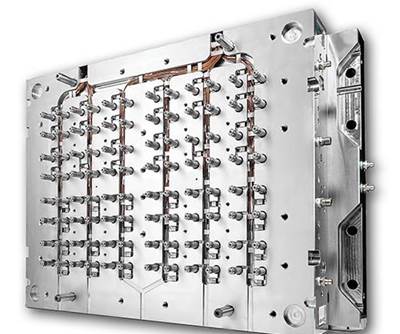

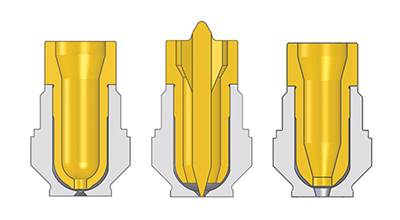

Read MoreHot Runners: A View from the Bottom Up

Addressing hot-runner benefits, improvements, and everyday issues from the perspective of decades of experience with probably every brand on the market. Part 1 of 2.

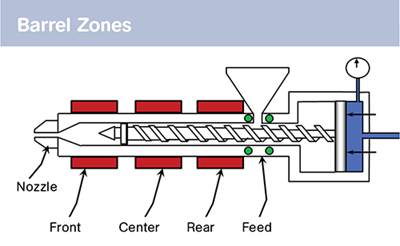

Read MoreMelt Preparation Part 1: Melt Temperature Optimization

A homogenous melt is required for consistent part quality, but achieving it requires balancing a number of factors, including barrel usage and temperature as well as screw speed, backpressure and residence time. Learn how to prepare your melt for molding success in this two-part series.

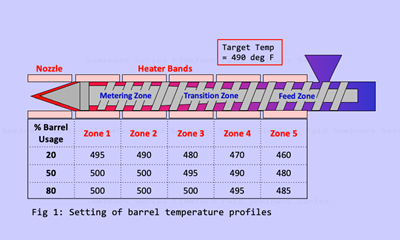

Read MoreHow to Set Barrel Zone Temps in Injection Molding

Start by picking a target melt temperature, and double-check data sheets for the resin supplier’s recommendations. Now for the rest...

Read MoreThe Strain Rate Effect

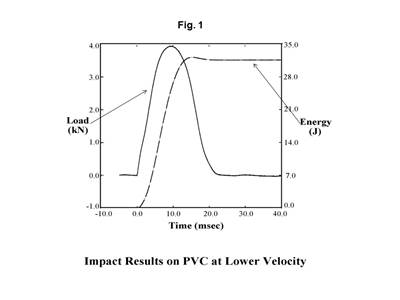

The rate of loading for a plastic material is a key component of how we perceive its performance.

Read More