best practices

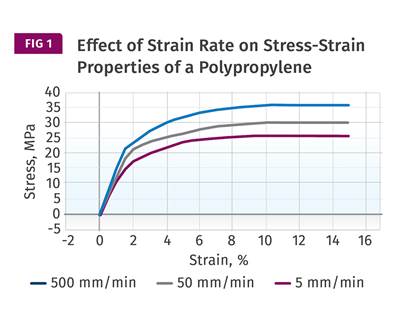

Understanding Strain-Rate Sensitivity In Polymers

Material behavior is fundamentally determined by the equivalence of time and temperature. But that principle tends to be lost on processors and designers. Here’s some guidance.

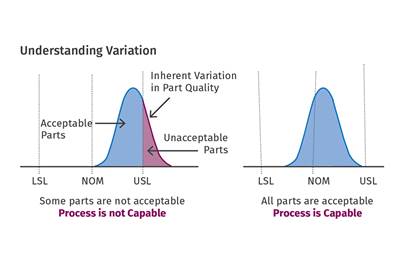

Read MoreCreating a Capable Process Using Process Capability

Know your Cp from your Cpk and how parts can meet dimensional specifications but still not be “capable.”

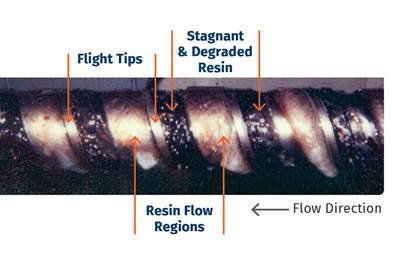

Read MoreHow Screw Design Can Mitigate Gels in PE Films

Gels are a constant issue in production of PE films using single-screw extruders. Gels can create quality issues via optical flaws, and they can cause the film to break on blown or cast film lines. There are numerous origins for gels, and the mitigation method depends on knowing the gel type.

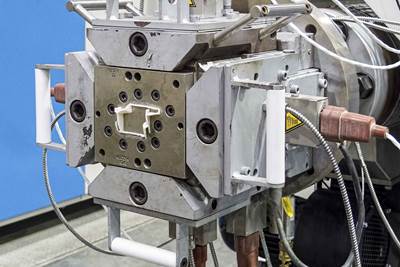

Read MoreHow to Set Up Mold Protect on Your Injection Machine

Set the start position for mold protect where anything in the mold could be subject to damage.

Read MoreFollow These Tips to Maximize Purging Efficiency

Commercial purging compounds offer dedicated solutions to your equipment cleaning needs, but some can be more effective in cleaning the ‘dead areas’ in certain screws and tooling. Follow these tips to choose the right one for your application, and make sure to follow the right protocol when shutting down for long periods.

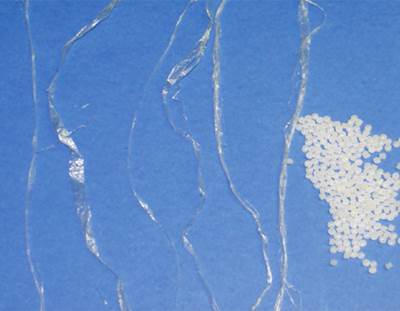

Read MoreSix Tips to Prevent Those Annoying Streamers

Streamers are a vexing problem that can foul up production. If you have time and budget constraints, there “at-home” solutions you can try. But once you’ve exhausted those routes, you might have to throw a little money at the problem. Here’s a process engineer’s view of things.

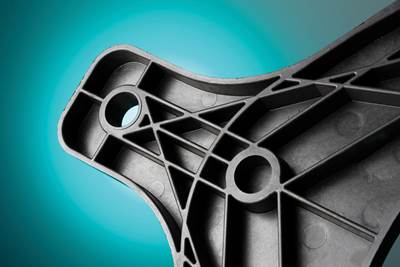

Read MoreThe Long and Short of It (Part 2)—Tips for Molding Short-Fiber Reinforced Polymers

Following on a similar guide for long-fiber reinforced compounds, here are practical tips on designing and injection molding parts utilizing short-fiber reinforcements.

Read MoreRevisiting the '5 M's' of Molding

All injection molding ultimately comes down to the “Man, Mold, Machine, Material and Method.” But those key aspects can be viewed differently if you’re auditing mold changes before startup or troubleshooting changes for an already validated process.

Read MoreIs Your Profile Die the Problem? Or Is It the Heaters?

When a profile is not being extruded to the tolerances of previous runs, the die is often suspect—but the real problem may be the heaters. Learn the five heater-band principles before you do any profile die work.

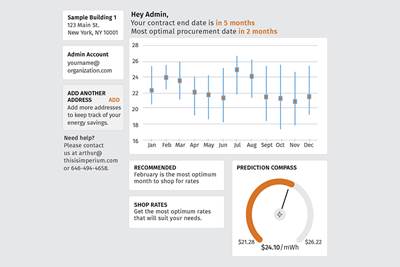

Read MoreService Helps Manufacturers Buy Energy When the Time is Right

Insulating manufacturers from market volatility can pay off big, as one firm can attest.

Read More